| |

due to the lower formability of the "cold"

material and the bigger contact stresses between workpiece and tooling.

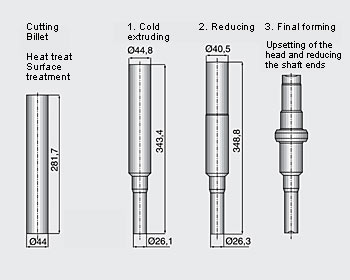

The most important cold-forming process is extrusion. With this

process, the material is pressed through a tool nozzle. The parts produced

are generally axisymmetric. It is less common for parts with secondary

elements to be produced by cold forming. As the final geometry cannot be

achieved via a single forming process, cold massive forming processes are

generally used in combination, namely in sequential forming stages. The

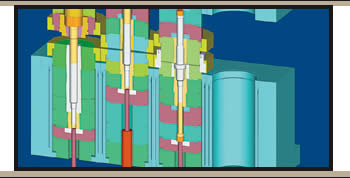

animation shows the production sequence for a cold-extruded transmission

shaft which is produced by forward direct extrusion, free reduction and

upsetting.

Therefore, a suitable choice of material (steel) is

essential to cold-forming, as is the special pre-treatment of the

workpiece in order to optimize microstructure and surface for the

subsequent forming process, as well as a special tool technology. In

addition to various non-ferrous metals, unalloyed and low alloyed steels

are the preferred materials for cold forming. These materials should

exhibit a carbon content of less than 0.5% and the content of the other

alloying components should be less than 5%. Other material elements such

as sulfur or phosphorous should only be present in minimal amounts (max.

0.035%). The formability of the microstructure is thus optimized prior to

forming by annealing on spheroidal cementite (so-called spherodize

annealing).

|

|

|

![]()

|

.gif) |

.gif)

Sequence of

forming stages in the production of a transmission shaft

| |